Milestone Highlights & Solution Updates

Dear iSensPro Friends,

As we move further into 2025, we’re pleased to share a few highlights from the journey so far. Over the past months, we’ve made steady progress across our solution, partnerships, and technology foundation—all with one clear goal: helping asset owners detect, monitor, and respond more intelligently to CUI.

Milestone Updates -Projects

Monitoring Begins at BASF Antwerp

After conducting CUI inspections at various pipe locations using our handheld sensors during the summer of 2024, BASF Antwerp has taken the next step toward automation. Non-ATEX fixed sensors have now been installed to enable continuous monitoring of insulated pipelines across several tens of meters. This marks a significant move toward scalable, data-driven asset integrity management.

Details to follow as the project progresses-stay tuned.

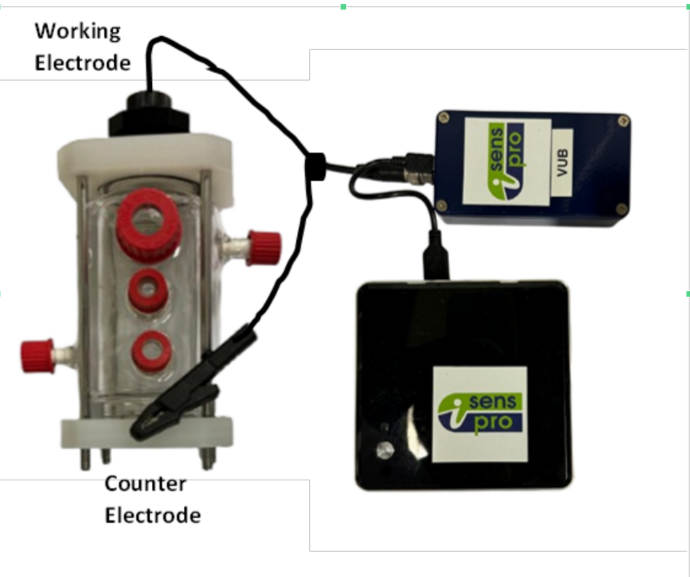

VUB-CUI Research Finalized

In collaboration with the Research group SURF of the University of Brussels (VUB), our sensor technology was evaluated and validated for measuring the water uptake and degradation of coatings in comparison with the more conventional Electrochemical impedance spectroscopy. This project provided us the insights to link the physical behavior of insulated and coated systems with the measured data from our sensors. With the developed data analytics we can now provide information on the conditions of insulated assets rather than just data points to be interpreted by the inspection expert.

Stay tuned for a detailed report

OptiHeat+ Innovation Project Launched

iSensPro is participating in a 3 year research project funded by

the Flemish Government to develop solutions for the automated fault

detection and diagnosis in district heating networks. Together with

Luminus and Fluvius, two district heating network operators in Flanders,

iSensPro will evaluate the feasibility of its sensor-technology to be

used for leakage and corrosion detection of underground pipelines. This

will open new market opportunities towards the growing energy domain.

Milestone Highlights-Global Growth

Our technology is now live with seven customers worldwide, delivering

value through inspection and monitoring capabilities—with consistently

positive feedback and high satisfaction across the board.

The iSensPro Handheld Sensor continues to be adopted internationally, supporting precision inspections and quick deployment.

Thanks to our growing community! We're excited to keep sharing insights, updates, and real-world applications with you.

Solution Highlights: Smarter Asset Management with AI-4-IA

Alongside key milestones, we’ve continued to advance our solution. Our AI-4-IA(Artificial intelligence platform brings together sensing, analytics, and reporting to help asset owners take control of maintenance, monitoring, and long-term performance.

What It Delivers:

Continuous Monitoring & Real-Time Detection: Our iSens solution includes monitoring with fixed ATEX and non-ATEX sensors for continuous, real-time detection of Corrosion Under Insulation (CUI), and inspection using our handheld sensor for fast, accurate spot checks and localization. These capabilities are further enhanced by radiography and third-party tools, offering a full-spectrum approach to asset integrity.

Centralized Asset Intelligence with iCollect: Aggregates sensor data using AI-powered search and dashboard tools, providing a unified view of asset health and performance.

AI Learning & Predictive Diagnostics with iLearn: Identifies anomalies, issues alerts, and recommends maintenance actions—learning from every intervention to enhance accuracy over time.

Actionable Insights with iKnow: Converts asset data into reports that support operations, planning, purchasing, safety, and sustainability strategies.

Why it Matters:

AI-4-IA empowers industrial

teams to take control of asset integrity—reducing unplanned

downtime, improving asset longevity, lowering maintenance costs,

and enabling proactive decision-making through

predictive analytics.

Click here to read more about our smart infrastructure for Industrial assets